| Linea |

Family |

| Fittings and Piping |

Fittings for welding tubing |

| Application |

| Food, Power, Gas & Bellows; Cryogenic, Nuclear, Oil & Bellows; Gas, Chemical, Water Treatment |

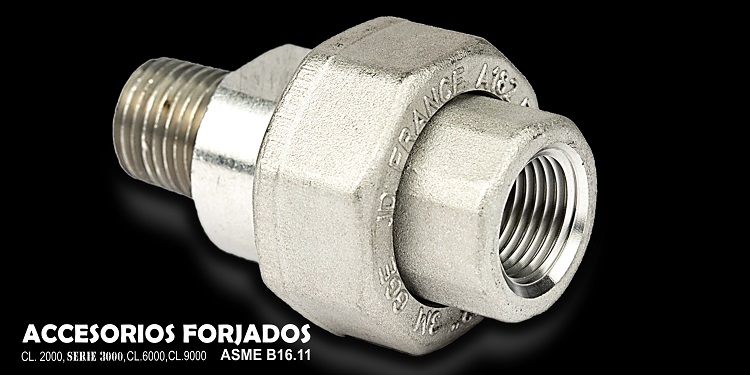

DESCRIPCIÓN:

Meceweld welding fittings are used exclusively for connecting to instrumentation piping. They are suitable for the assembly of high pressure circuits with a high degree of responsibility subjected to the harshest and most variable working conditions. The main part of the fittings is their specially machined connection nipple or socket with rigorous tolerances. They have been analytically determined from the general requirements of

ASME B31.1, ASME B16.11 and ASME B16.34.

They are manufactured in two types of materials: 316 grade stainless steel, carbon steel and brass. On request we can manufacture 304 Stainless Steel, Hastelloy, Inconel, among others (see Special Materials catalog).

Stainless steel fittings are supplied pickled and passivated and carbon steel fittings are phosphated.

In inches, from 1/4 "O.D. (6.35 m.m.) to 1 "O.D. (25.4 m.m.); in millimeters, from 6 to 20 m.m. Fittings for other pipe dimensions can be supplied upon request. To connect black Pipe (ASME B36.10 M, ASME B36.19M) to calibrated pipe (Tubing), a mixed adapter is provided to allow this variant.

Each working pressure is calculated for a temperature range from -10ºF to 100ºF (-29ºC to 38ºC). The operating conditions for other temperatures can be determined from the following equation:

Pt = (Pn*K)/1000 = (Bar)

Pt = Working pressure at the desired temperature.

Pn = Working pressure of the fitting according to its corresponding section and reference.

K = Correction coefficient (Catalog Tables).

Do not use 316 grade stainless steel fittings where the service temperature may exceed 1000°F (538°C).

For 316 grade stainless steel fittings where the service temperature may exceed 1000ºF (538ºC), this should be indicated in the order.

Prolonged use of carbon steel at temperatures above 800ºF (427ºC) is not recommended.