| Línea | Familia |

|---|---|

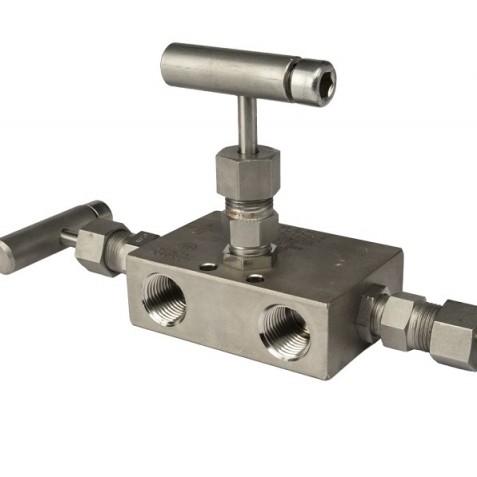

| Manifolds | MC Series: Manifols max pressure de 420 bar (6000 psi) |

| Aplicación |

|---|

| Alimentaria, Energética, Gasística & Criogénica, Nuclear, Oil & Gas, Química, Tratamiento de aguas |

| Línea | Familia |

|---|---|

| Manifolds | MC Series: Manifols max pressure de 420 bar (6000 psi) |

| Aplicación |

|---|

| Alimentaria, Energética, Gasística & Criogénica, Nuclear, Oil & Gas, Química, Tratamiento de aguas |

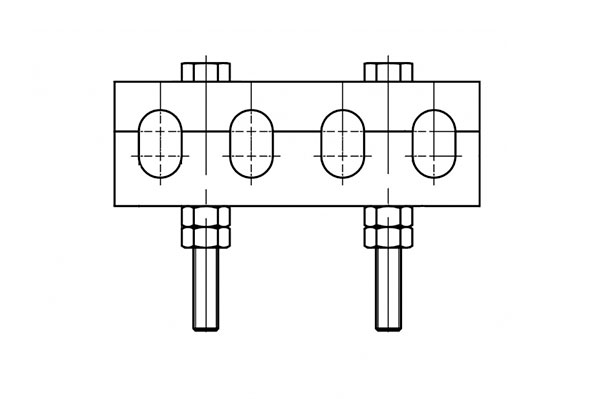

| Linea | Family |

|---|---|

| Manifolds | MC Series: Manifold max pressure 420 bar (6000 psi) |

| Application |

|---|

| Food, Power, Gas & Bellows; Cryogenic, Nuclear, Oil & Bellows; Gas, Chemical, Water Treatment |

| Linea | Family |

|---|---|

| Fittings and Piping | Instrumentation clamp |

| Application |

|---|

| Food, Power, Gas & Bellows; Cryogenic, Nuclear, Oil & Bellows; Gas, Chemical, Water Treatment |

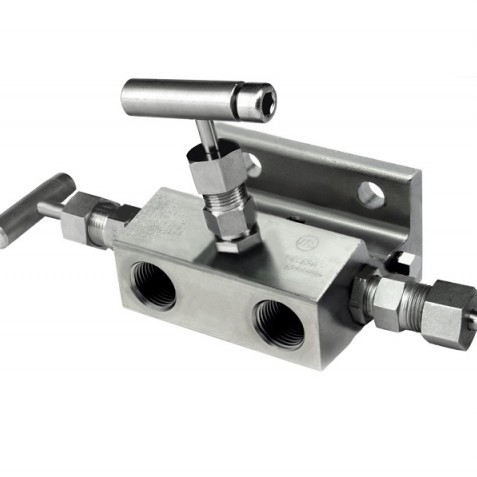

| Linea | Family |

|---|---|

| Manifolds | MC Series: Manifold max pressure 420 bar (6000 psi) |

| Application |

|---|

| Food, Power, Gas & Bellows; Cryogenic, Nuclear, Oil & Bellows; Gas, Chemical, Water Treatment |

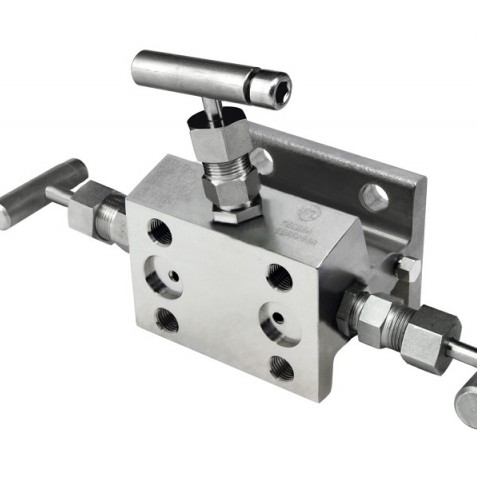

| Linea | Family |

|---|---|

| Manifolds | MB Series: Manifold Max pressure 250 bar |

| Application |

|---|

| Food, Power, Gas & Bellows; Cryogenic, Nuclear, Oil & Bellows; Gas, Chemical, Water Treatment |

| Linea | Family |

|---|---|

| Manifolds | MB Series: Manifold Max pressure 250 bar |

| Application |

|---|

| Food, Power, Gas & Bellows; Cryogenic, Nuclear, Oil & Bellows; Gas, Chemical, Water Treatment |

| Linea | Family |

|---|---|

| Manifolds | MB Series: Manifold Max pressure 250 bar |

| Application |

|---|

| Food, Power, Gas & Bellows; Cryogenic, Nuclear, Oil & Bellows; Gas, Chemical, Water Treatment |

| Linea | Family |

|---|---|

| Manifolds | MB Series: Manifold Max pressure 250 bar |

| Application |

|---|

| Food, Power, Gas & Bellows; Cryogenic, Nuclear, Oil & Bellows; Gas, Chemical, Water Treatment |

| Linea | Family |

|---|---|

| Manifolds | MB Series: Manifold Max pressure 250 bar |

| Application |

|---|

| Food, Power, Gas & Bellows; Cryogenic, Nuclear, Oil & Bellows; Gas, Chemical, Water Treatment |

| Línea | Familia |

|---|---|

| Manifolds | MC Series: Manifols pressure 420 bar (6000 psi) |

| Aplicación |

|---|

| Alimentaria, Energética, Gasística & Criogénica, Nuclear, Oil & Gas, Química, Tratamiento de aguas |

| Linea | Family |

|---|---|

| Manifolds | MB Series: Manifold Max pressure 250 bar |

| Application |

|---|

| Food, Power, Gas & Bellows; Cryogenic, Nuclear, Oil & Bellows; Gas, Chemical, Water Treatment |

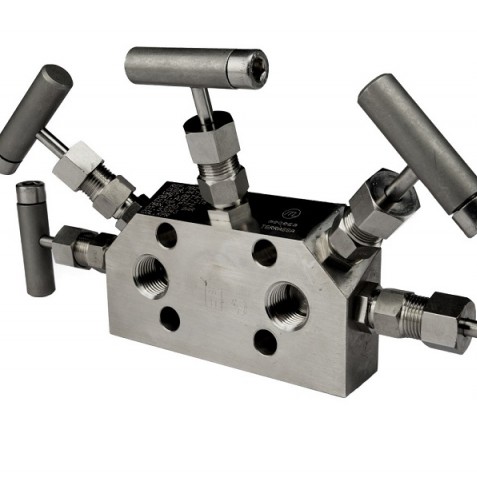

| Linea | Family |

|---|---|

| Manifolds | MC Series: Manidold Max pressure 420 bar (6000 psi) |

| Application |

|---|

| Food, Power, Gas & Bellows; Cryogenic, Nuclear, Oil & Bellows; Gas, Chemical, Water Treatment |