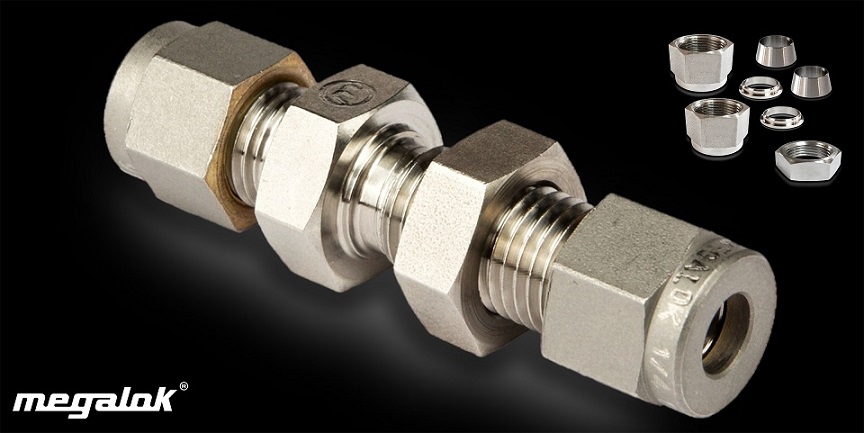

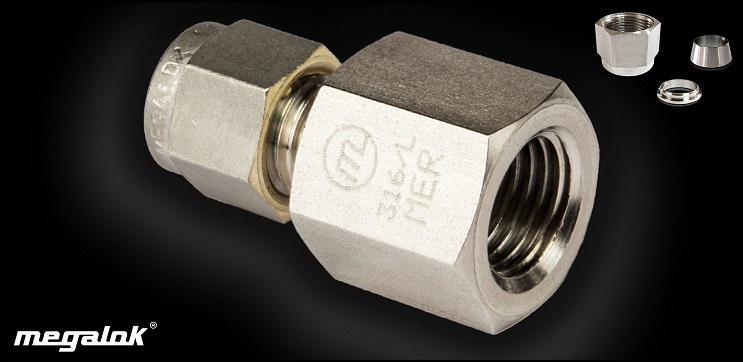

| Linea |

Family |

| Fittings and Piping |

Tube |

| Application |

| Food, Power, Gas & Bellows; Cryogenic, Nuclear, Oil & Bellows; Gas, Chemical, Water Treatment |

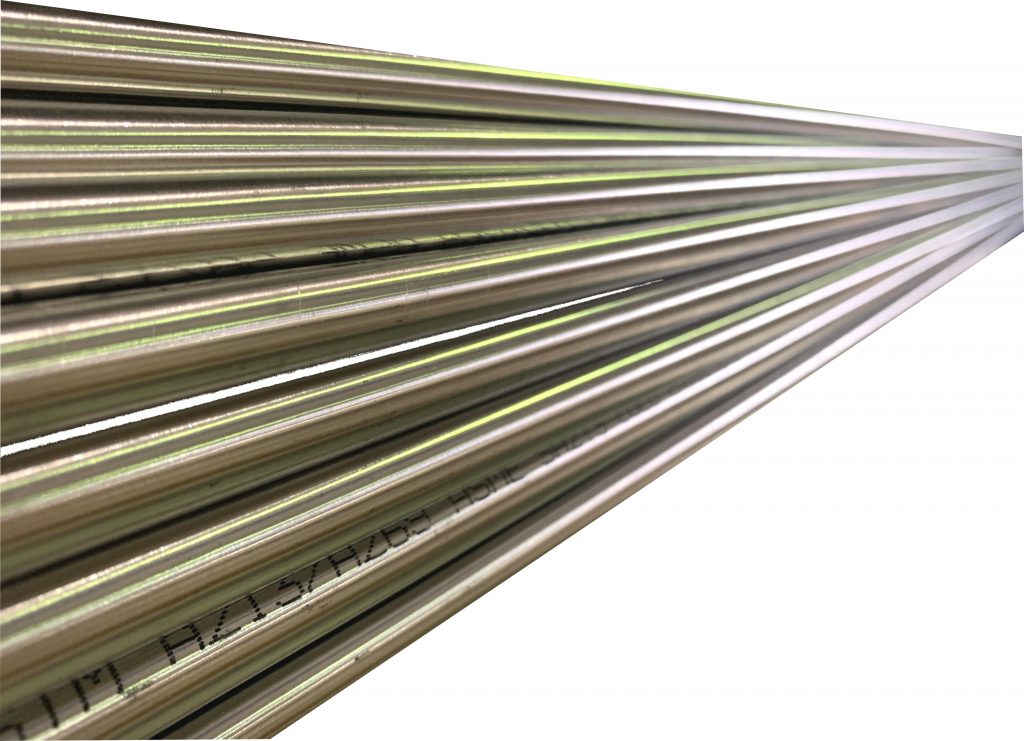

DESCRIPCIÓN:

STAINLESS STEEL, COPPER AND PLASTIC PIPES

AND MULTITUBES

- Stainless Steel and Carbon Steel Pipes

- Copper Pipes

- Copper pipes with PVC insulation

- Multipipes, steam traced and electric traced pipes

STAINLESS STEEL:

ASTM A 269 corrosion resistant, seamless, general purpose austenitic stainless steel tubing.

Austenitic stainless steel tubes ASTM A 213 seamless for boilers, superheaters and heat exchangers.

Pressure calculations are based on ASME B31.3 in accordance with ASTM A213 / A269 tolerances.

Calculation temperature from -20°F to 100°F ( -29°C to 38°C).

Certified tests:

Flaring tests.

Rockwell surface hardness < B90.

Crush test.

Hydrostatic test.

COPPER:

Annealed copper tubes :

ASTMB68/ASTMB75

ASTM B 88 (Type K / Type L)

Black PVC coated copper tubes:

ASTMB68/ASTMB75

Chemical characteristics (Table 1. ASTM B 68, ASTM B 75 and ASTM B 88).

Copper UNS No. C12200

Minimum Copper % 99.9

Phosphorus % 0.015 to 0.040

Calculations made from ASME B31.3 specifications based on a minimum copper stress of 30 Ksi at -20°F to 100°F (-29°C to 38°C) in accordance with the diameter and wall thickness tolerances for each standard.